There are typically two different types of diffraction grating – the ruled grating and the holographic grating.Ī ruled diffraction grating is produced by a ruling engine that cuts grooves into the coating on the grating substrate (typically glass coated with a thin reflective layer) using a diamond tipped tool.Ī holographic diffraction grating is produced using interference lithography which results in a smooth groove surface and eliminates the periodic errors found in ruled gratings.Ī diffraction grating can be a reflection grating or a transmission grating. The groove density, depth and profile of a diffraction grating dictate the spectral range, efficiency, resolution and performance of the diffraction grating. micro:bit the robot.A diffraction grating is an optical element that diffracts energy into its constituent wavelengths.

Miguel Ayuso Parrilla wrote a reply on DIY hobby servos quadruped robot.kelvinA has added a new log for SecSavr Suspense.Miguel Ayuso Parrilla has added a new log for DIY hobby servos quadruped robot.Stephen Chasey has added a new log for Nerdfeeder.kelvinA has updated the project titled SecSavr Suspense.Marcel has updated the log for Fresh air automation by RF usb dongle.Neal liked Raspberry Pi SuperCapacitor UPS with Power Switch.KSanger on New OS For Commodore 64 Adds Modern Features.

DIFFRACTION FILM PORTABLE

Meanwhile, consider diving deeper into the world of 3D printed optics!

DIFFRACTION FILM HOW TO

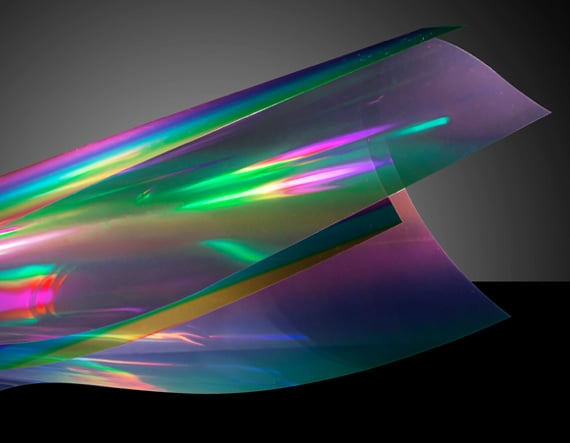

It’s a great in-depth guide on how to get diffraction grating prints right. It also bears noting that the print won’t survive excessive handling, as the grating structures will get damaged by physical touch. recommends using a freezer to help separate the parts from the grating surface. Naturally, removing the print must be done delicately, lest one disturb the delicate structures key to generating the iridescent effect. Again, the temperature at which the diffraction grating itself can survive is important to take into account going above 90 degrees can be risky here. The guide also shows two methods of achieving the goal: one can either use an off-the-shelf grating, or one can prepare a no-longer-wanted CD into a suitable print surface. Setting the Z-offset appropriately can help here.Ĭhoosing the right bed temperature is also important to ensure the molten plastic is able to flow into the grooves of the grating. Too high and the grooves won’t transfer to the plastic, and too low, and it’s likely you’ll just melt the grating itself. This is because the first layer of plastic has to meld perfectly with the diffraction grating to pick up the pattern. Getting the bed as close to perfectly level is key here, as is the first layer height. We’ve seen similar work before, but the guide from goes into greater detail on how to get the effect to work just right. It’s a great way to add iridescence and shine to a print. Instead, by 3D printing onto an existing diffraction grating, the print can pick up the texture on its base layer. You can 3D print a functional diffraction grating, too, with the right techniques, as it turns out! The average 3D printer can’t recreate the tiny-scaled patterns of a diffraction grating directly a typical diffraction grating may have up to 1000 lines per mm. It’s the same effect you see on the bottom of a CD! Diffraction gratings are beautiful things, bending transmitted and reflected light and splitting it into its component wavelengths to create attractive iridescent rainbow patterns.

0 kommentar(er)

0 kommentar(er)